The right chemistry for wellbore cleanup

/Most of the work we do at SAS Production Services is in wellbore remediation and stimulation services. We have some amazing filtercake breaker products that uniquely do not require separate acids or acidizing products. We can delay your filtercake from breaking by several days and our technical team is constantly pushing back how long we can provide the delay for. It is impressive stuff.

Today however I want to put forward a less talked element of our work. This is the use of our unique chemistry in wellbore cleanup. Our first downhole work actually was in this application and for some three years we worked with ExxonMobil in the North Sea. The work was an absolute success for a number of reasons.

A simplified process

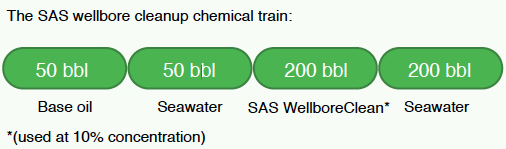

First of all our chemistry greatly simplified the wellbore cleanup process. Both at surface and in the well the reduction of the number of pills made things a lot easier to handle for the team on the rig. Some of the worst wellbore cleanup programs we have seen had over 20 cleanup pills. All of these have to be prepared, kept separate and pumped at the right time. This increases the number of people required and complicates rig logistics.

With our approach and highly effective chemistry it is possible to use a cleanup train of 3 – 4 pills. Because our chemistry is so effective in removing all mud traces the brine is also returned to specification much faster. This reduces brine requirements and reduces filtration needs.

Microemulsion chemistry

Secondly the unique microemulsion chemistry makes it possible to let the returning slops phase separate under gravity in the pits on the rig. This means a waste reduction of 70 – 97% compared to normal emulsion forming detergent pills.

That the simple change of a standard detergent to the use of our microemulsion can have such a magnificent impact was unexpected for ExxonMobil and for the waste management company involved. The waste management company simply had to leave the waste to stand in a tank and the next day all was nicely separated in oil, water and solids.

Those are the results we can achieve for you as well. We can reduce your chemical consumption by 65%, we can reduce your surface logistics tremendously and we can reduce your slops waste by over 70%.

Give us a call and let’s talk.